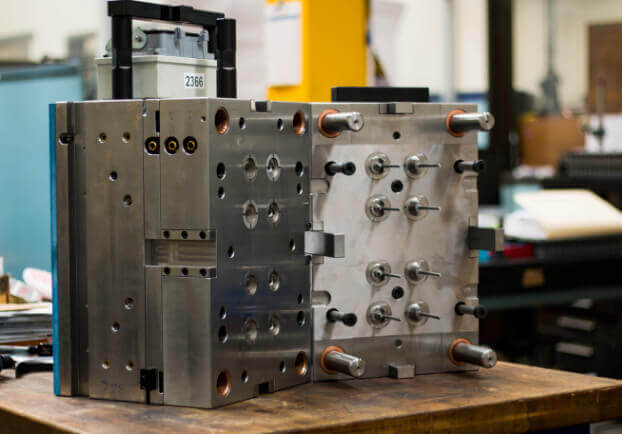

Production Tooling

Request a Quote

40+ years of experience

ITAR Registered

ISO9001: 2015 Certified

High-Volume Injection Molding

At TenX Manufacturing, we pride ourselves on our cutting-edge Production Injection Mold Tooling capabilities that set us apart in the industry. Specializing in high-end solutions, we offer a comprehensive suite of services that cater to the unique needs of our clients.

From multi-cavity tools enhancing production efficiency to the strategic integration of automation, such as End-Of-Arm-Tooling (EOAT), our commitment is to deliver not only cost-effective solutions but also to maintain the highest standards of quality. With both tooling and molding capabilities housed under the same roof, our facility fosters seamless collaboration between our skilled toolmakers and process engineers. Throughout the entire production cycle, from tool design to part sampling and beyond, our team works cohesively to ensure precision, consistency, and adherence to ISO9001:2015 certified process control procedures. This holistic approach not only accelerates production timelines but also provides our customers with confidence in the reliability and excellence of our services.

Cost Efficiency

The use of multi-cavity tools and automation keeps production costs down.High Efficiency

Reduced cycle times and streamlined processes lead to higher production efficiency.Consistent Quality

Automation and collaborative efforts result in consistently high-quality parts.Single-Facility Advantage

Having both tooling and molding capabilities in one facility minimizes logistical complexities and accelerates the production timeline.ISO9001:2015 Certification

Customers gain confidence in our commitment to quality and adherence to internationally recognized standards.TenX Manufacturing stands as a beacon of commitment to excellence through the seamless collaboration of skilled toolmakers and process engineers. Our integrated approach, marked by real-time communication and swift issue resolution, optimizes the production workflow. With ISO9001:2015 certification validating our stringent quality control, we ensure traceability, reliability, and continuous improvement in every stage of production. In essence, TenX Manufacturing’s Production Tooling services epitomize a holistic, high-precision, efficient, and quality-driven solution, seamlessly integrating High-End Production Tooling, Multi-Cavity Tools, and Automation for comprehensive manufacturing excellence.

Other Injection Molding Services

PROTOTYPE & MID-VOLUME PARTS

For quantities ranging from 100 to 100,000 parts, TenX can product parts with rapid turnaround times and precise execution. Learn MorePrototype Tooling

Class 105 & 104 Injection Mold Tooling built to satisfy both prototypes & low/mid-volume injection molded part requirements. Learn MoreHIGH-VOLUME PRODUCTION PARTS

When the need is for 100,000 to Millions of parts, TenX has the capacity to accommodate your injection molded needs. Learn MoreNeed a quote?

Use our quote form. Upload your files and tell us your project details.

Request a Quote