5TH AXIS CAPABILITIES

Get a Quote

40+ years of experience

ITAR Registered

ISO9001: 2015 Certified

About 5th Axis Capabilities

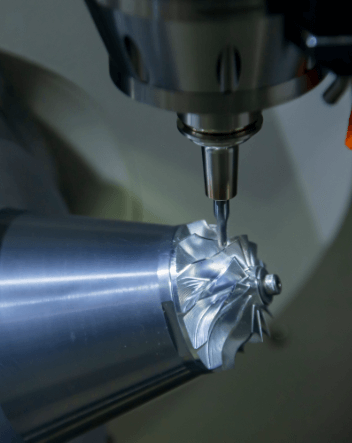

The introduction of the A and B axis enables the cutting tool to approach the workpiece from multiple angles, facilitating the machining of complex shapes and contours that would be challenging or impossible with traditional 3-axis milling. This capability is particularly valuable in industries such as aerospace, automotive, and medical manufacturing, where intricate and precise components are often required.

5th-axis milling machines are equipped with a rotary table or other mechanisms that enable the simultaneous movement along all five axis, providing a high degree of flexibility in manufacturing complex parts with a single setup.

Additional Resources

CNC Milling

Involves removing material from a workpiece using rotary cutters to create complex shapes and features. Learn MoreCNC Turning

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. CNC lathes or turning centers have tooling mounted on a turret which is computer-controlled. Learn MoreDesign for Manufacturing

Design for Manufacturing (DFM) is a set of principles and practices aimed at optimizing the design of a product to enhance its manufacturability and efficiency in the production process. The goal of DFM is to create a product design that is not only functional and meets the intended purpose but also takes into consideration the ease of manufacturing, assembly, and overall production cost. Learn More